Meat Grinder Machine

Videos in Youtube: https://youtu.be/uMXmNlKpTGU

Introduction

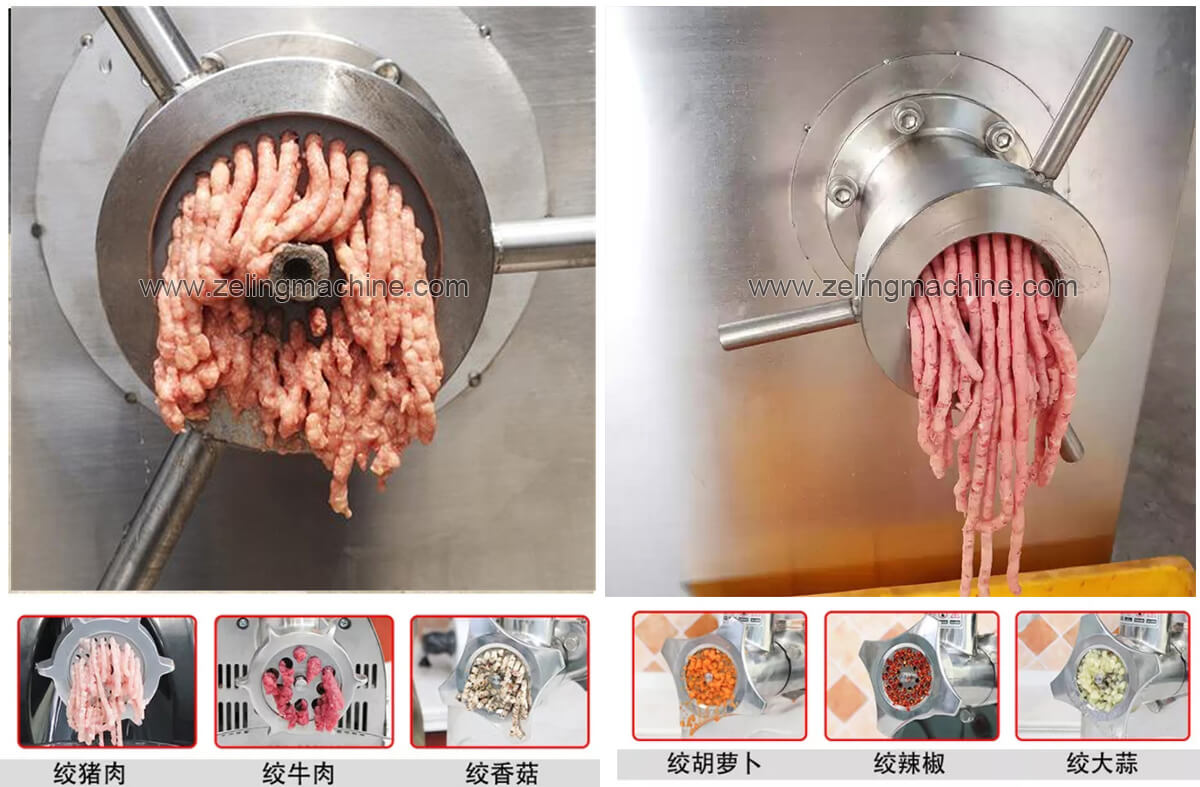

Frozen meat grinder machine relies on the screw to push the raw meat in the hopper box to the pre-cutting plate, and the orifice plate and the reamer are relatively operated by the rotation of the screw to cut the meat into granular shapes to ensure that the meat is uniform size. Different specifications of meat filling can be obtained through different combinations of orifice plates.

| Model | Voltage | Power | Capacity | Weight | Size |

|---|---|---|---|---|---|

| ZL-M100 | 380v | 5.5kw | 500kg-800kg /h | 180kg | 850*500*860mm |

| ZL-M120 | 380v | 7.5kw | 1000-1500kg/h | 260kg | 980x600x1080mm |

| ZL-M130 | 380v | 11kw | 1500kg-2000kg/h | 400kg | 1315x700x1100mm |

| ZL-M250 | 380v | 45kw | 2000-6000kg/h | 1200kg | 1800*1180*1360mm |

Our Advantage:

1.It adopts fully-enclosed gear transmission, with compact structure, stable operation, reliable work, and convenient maintenance.

2.The meat grinder head and food contact parts are made of food grade 304 stainless steel, which meets the requirements of the world’s highest food hygiene standards.

3.According to the technological requirements, different specifications of orifice plates can be selected to process the ideal meat filling to meet the processing requirements of different meat products.

Our Feature:

1.Combined with frozen meat slicer can effectively reduce the production cost and the temperature rise of raw meat to improve shelf life.

2.It can directly cut the un-thawing and make the meat grains with different specifications, without damaging the muscle fiber tissue.

3.This machine can directly grind unfrozen pieces of meat, reduce the loss of nutritional components and protein of the meat, and produce different meat products and meat pieces by changing the hole knife.